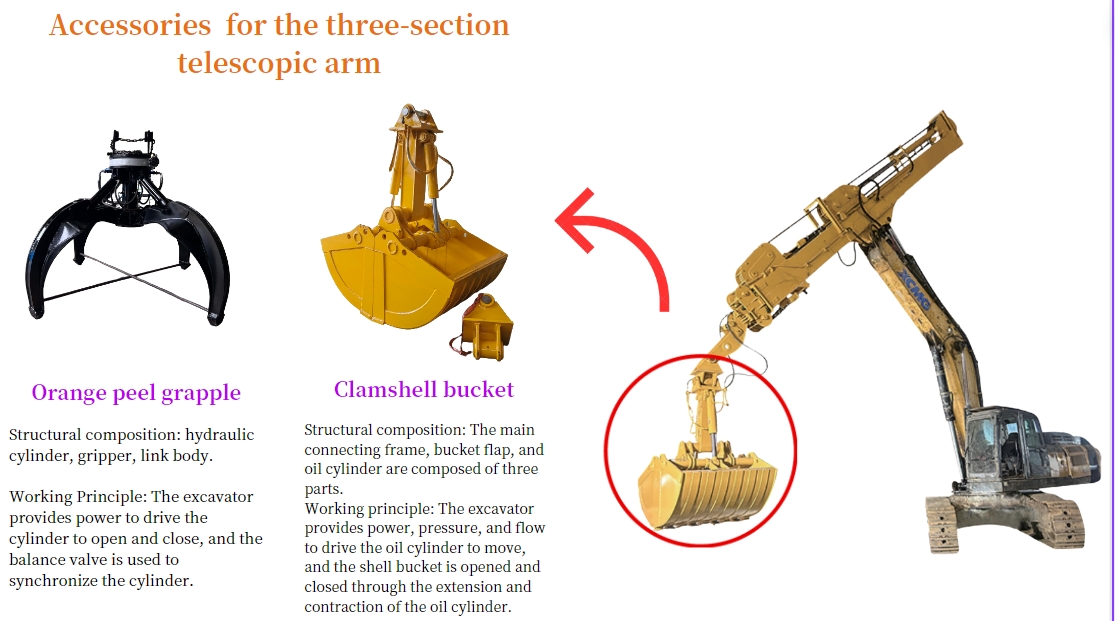

Our designs allow for interchangeable use of digging buckets and grab buckets.

The first one is clamshell bucket ,usually use for Subway deep digging project .

The second one is the grab bucket , compare to the clamshell bucket , the grab bucket have power

,can grab the stone.

The last is the standard bucket , use for telescopic boom the bucket need do the special design .

ZHONGHE triple quality control system

The first system is the technical design drawing review mechanism,

The second system is the semi-finished product review mechanism,

(each process has a detection testing for the previous process)

The third system is the finished product testing.

(Before painting, the overall inspection is carried out to check

whether the design size matches the welding size, and whether the

installation size meets the design requirement.)

To sum up, every single ZHONGHE product has been passed the above

three-stage inspection system to ensure that is qualified before

shipping.

About Our Company------Zhonghe Machinery

CE certification & Utility model patent certificates

Shipping And Packaging

Our products have been sold to more than 60 countries, and our

transportation methods include sea transportation, land

transportation, and air transportation. Our packaging is wooden box

packaging or stretch film packaging. The goods will be packed

before shipment and then loaded into the container to ensure the

safety of the goods.

Some questions and answers that may interest you

Q: Are you a manufacturer?

A: We are a manufacturer/supplier of excavator arms and attachments.

We have a super large factory. The factory area is several times

that of our competitors. It is the largest excavator attachment

factory in Guangdong Province. It has complete production equipment

and its products have been exported to more than 60 countries

around the world.

Q: Why does the telescopic arm have the difference between a shell

bucket and a grab bucket?

A: Generally, shell buckets are easy to use for silt and sand, and

can dig a large volume with higher efficiency. However, in general

sand and stone work, shell buckets have no digging force and are

limited by the opening, so the efficiency of shell buckets will be

reduced. Grab buckets are more suitable for this kind of work.

However, due to the overall weight of the grab bucket, the volume

of the grab bucket is generally smaller than that of the shell

bucket, but in work with more stones, the advantages of grab

buckets are more obvious.

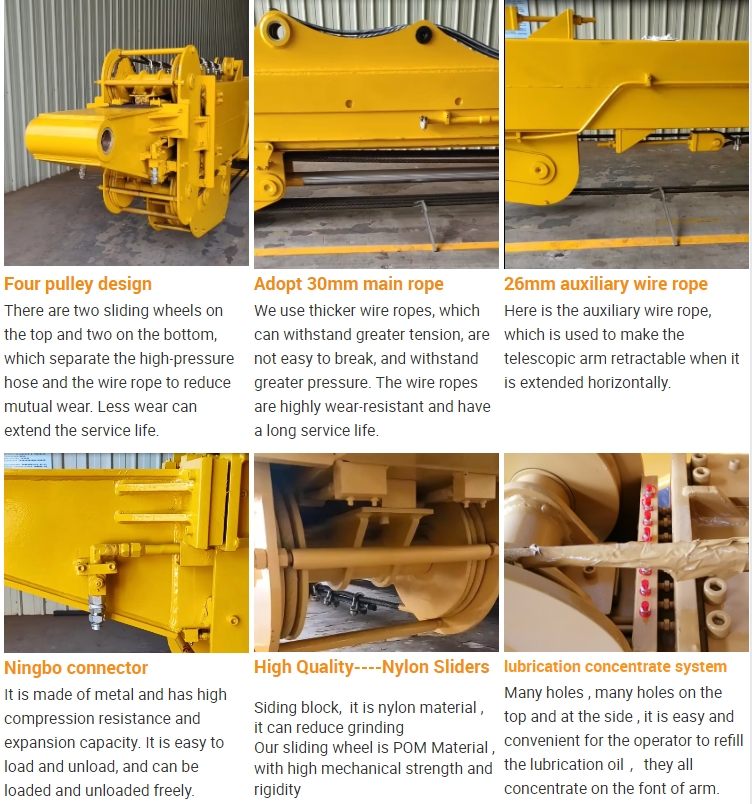

Q:Is it better to use a single cylinder or a double cylinder for

the shell bucket equipped with a telescopic arm?

A:We always use the double cylinder design and never use the single

cylinder design. It has the advantages of low failure rate,

convenient maintenance, and less oil leakage. What are the

disadvantages of the double cylinder? The first is that the shell

bucket with a double cylinder is heavier, and the synchronization

of grabbing is worse. The overall weight of a single cylinder is

lower, and the synchronization is better, the grabbing efficiency

is higher, but the failure rate is higher.

Q:What is the material of the telescopic arm?

A: The arm tube is made of BS900E, and other parts are made of

Q3558, which is lighter and more durable. We use a thickness of

6mm.

If you want to learn more details, just contact Ada

Whatsapp: +86 15322105263

Teil/Wechat: 0086 15322105263

E-mail: abby@excavatorboomarm.com